mps-tb

stainless steel T Transition

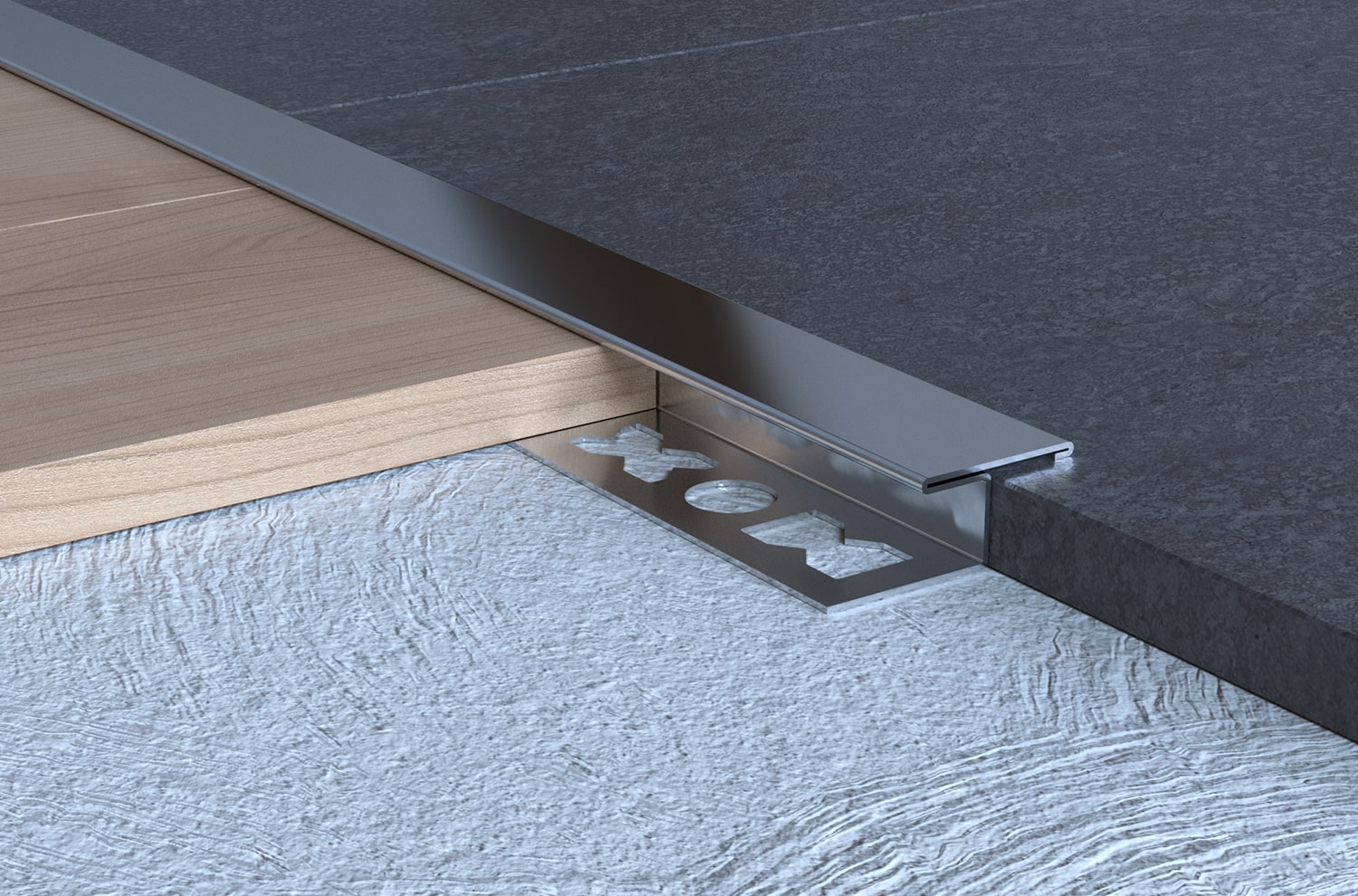

MPS-TB Stainless Steel Floor T Transition is one of the most durable transition profiles. Unlike its competitors it can be installed from its extension beneath the floorings and doesn't require adhesives which makes it more long-lasting. It covers the gaps and application flaws between floor transitions and door threshold transitions. It is also used as a separator frame in floor applications. It is extremely durable, long-lasting and corrosion resistant since it is produced from 304L quality stainless steel. 201 quality stainless steel alternative also available. MPS-TB has a traditional plain appearance for flooring transitions.

MPS-TB stainless steel floor T transition can be easily installed by pressing the perforated anchor extensions into the area where the adhesive is applied and then pressing the adjoining flooring material firmly into place. Corners can be assembled by cutting the profile to 45 degrees. It is available in 2438, 2500mm lengths and can be produced in any desired width or height.

MPS-TB stainless steel floor T transition has mirror, satin, exclusive super mirror surfaces and anthracite, bronze, copper, gold, inox color options.